400-897-3266

0769-87929358

0769-87929358

- Home

- High density sponge

- Sound insulation sponge

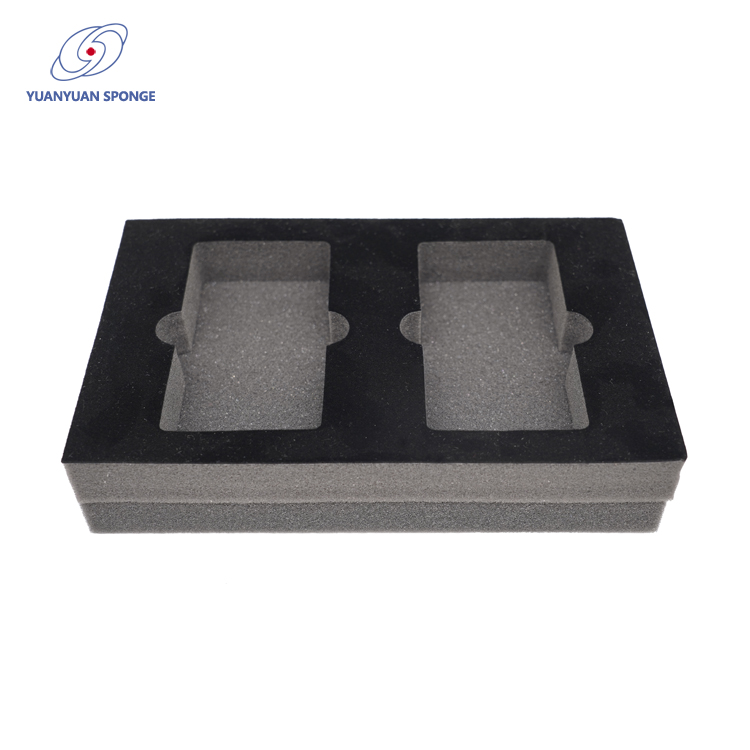

- Product High density sponge >Sponge sheet >Packaging sponge Sound insulation sponge >Sound absorbing sponge >Wedge shaped sponge with triangul... >Mushroom head sound insulation sp... Sponge products >Special shaped processing sponge >Toy sponge >Hydroponic planting sponge Flame retardant sponge >En71-2 flame retardant sponge >CA117 fireproof sponge >BS5852 flame retardant sponge Polyurethane sponge >Cleaning sponge >Bath sponge >Memory sponge Pu sponge >Pu self skinning >PU foam toys >Pu shaped sponge

- Service

- Case

- News

- About us

- Contact us

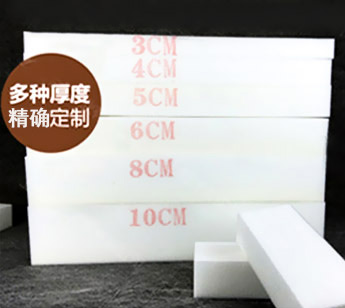

专用精密设备切割

专用精密设备切割

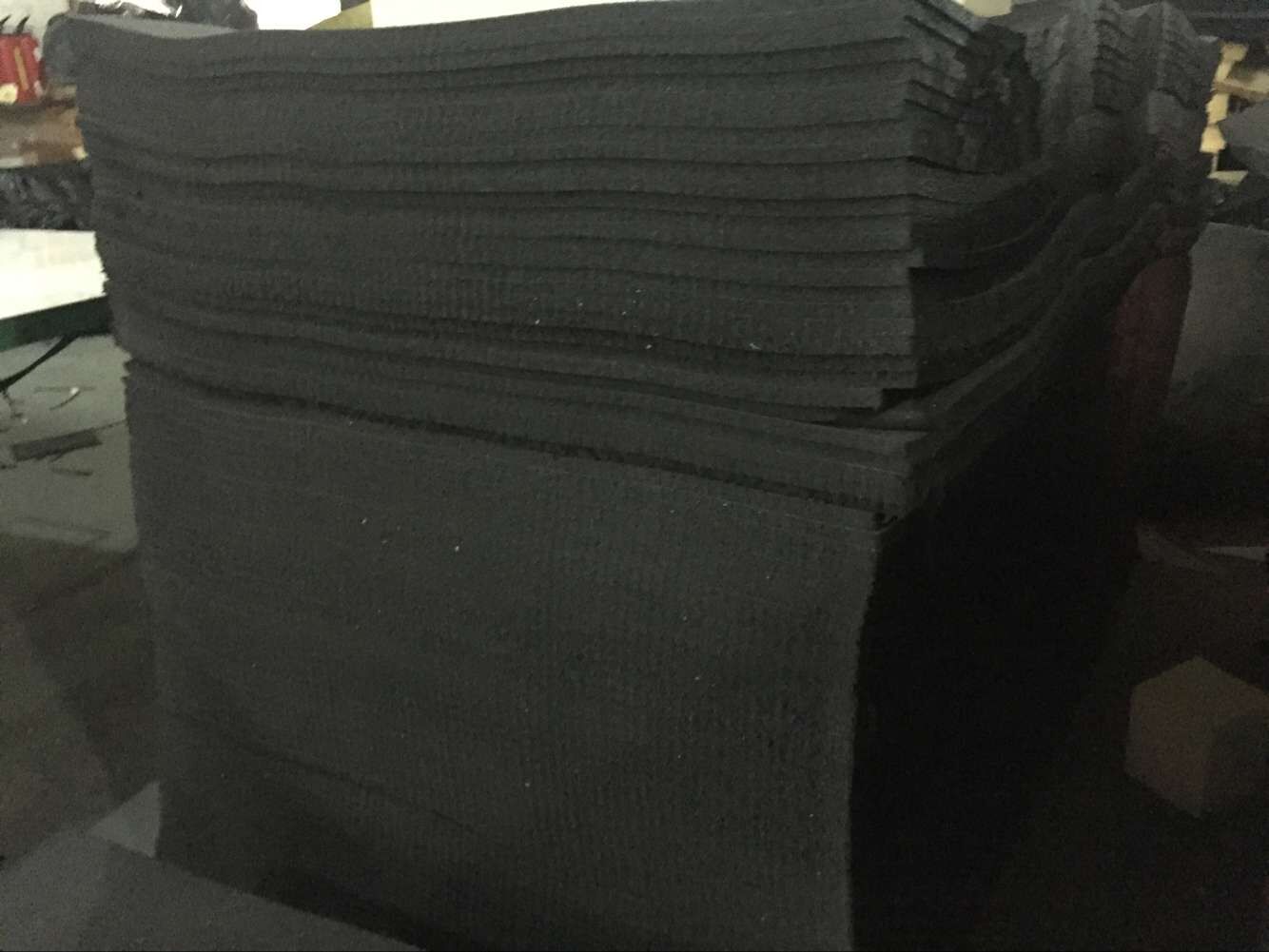

高韧性,使用寿命久,更加耐用

高韧性,使用寿命久,更加耐用

弹性十足,弯曲自如

弹性十足,弯曲自如