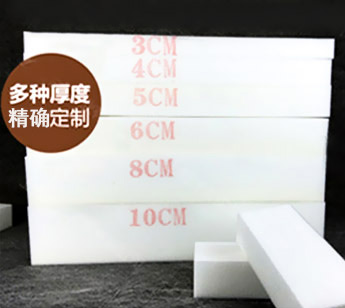

Product parameters

Product features

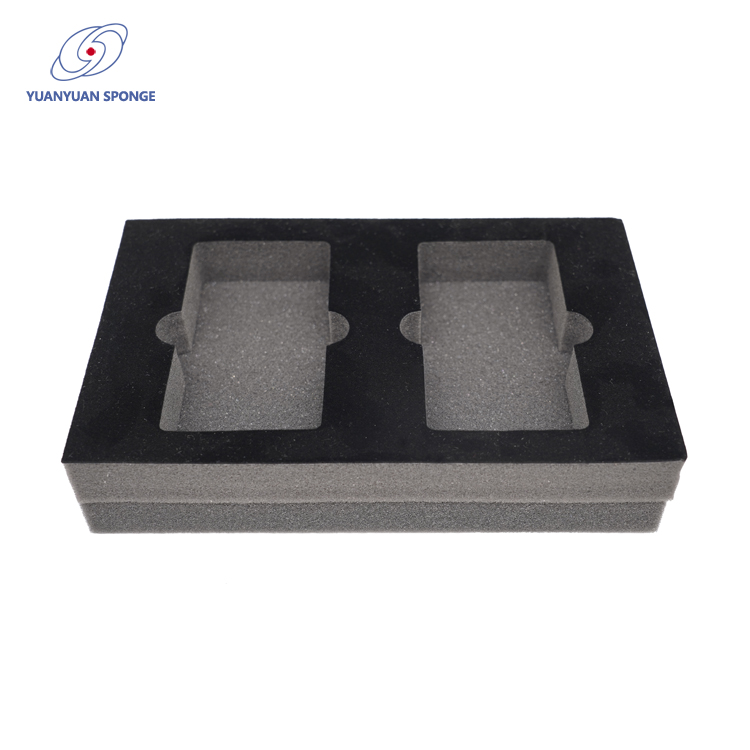

Sponge is an environmental protection material, which is suitable for high-end products' inner packaging and has the function of cushioning and shock absorption. Antistatic sponge not only protects electronic products and chips from general sponge, but also protects electronic products from electrostatic damage.

Because of its heat preservation, heat insulation, sound absorption, shock absorption, flame retardant, antistatic and good air permeability, sponge involves various industries, including automobile industry, battery industry, cosmetics industry, bra underwear manufacturing industry and high-grade furniture manufacturing industry.

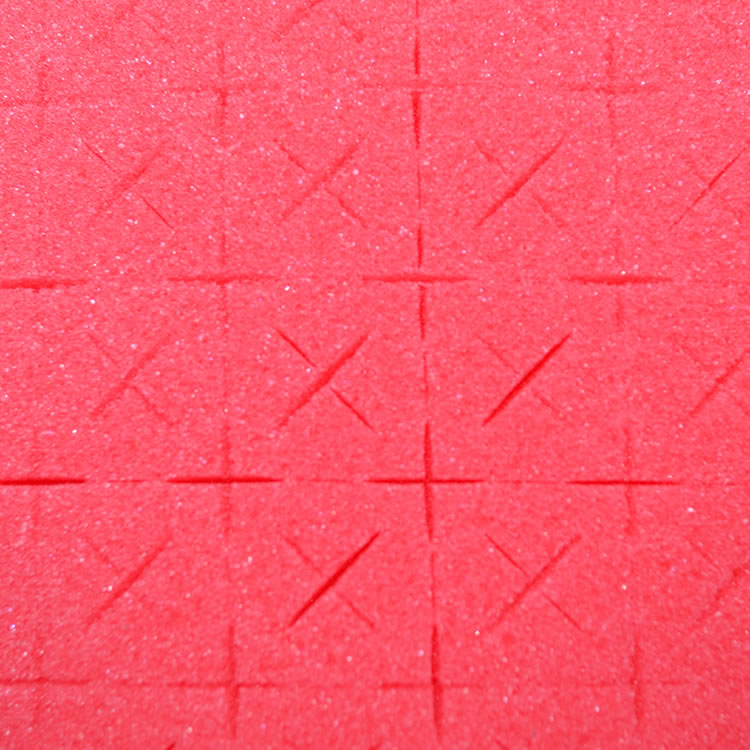

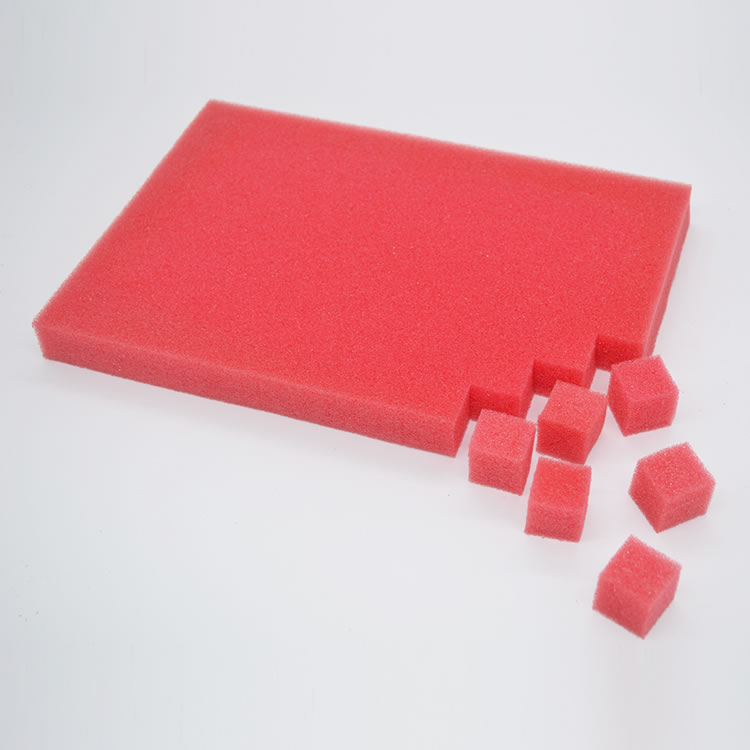

The sponge has delicate hand feeling, strong resilience, durable use, not easy to deform, smooth cutting. Sponge plays an important role in insulation, sealing, shockproof, dustproof, filling, sound insulation, fixing and beautifying products of all walks of life. Sponge is suitable for all telephone sets, mobile phones, computers, make-up gifts, speakers, toys, TV sets, lighting, lithium-ion batteries, car recorders, gift boxes and other supporting products. According to the customer's product size, color, shape and quality requirements, it can be processed into various special crafts and various shapes of sponge products

Scope of application

Packaging, toys, furniture, clothing, home textiles, shoes, cars, sports equipment, medical equipment and other fields

Customization process

Company strength

专用精密设备切割

专用精密设备切割

高韧性,使用寿命久,更加耐用

高韧性,使用寿命久,更加耐用

弹性十足,弯曲自如

弹性十足,弯曲自如